Description

ADVANTAGES

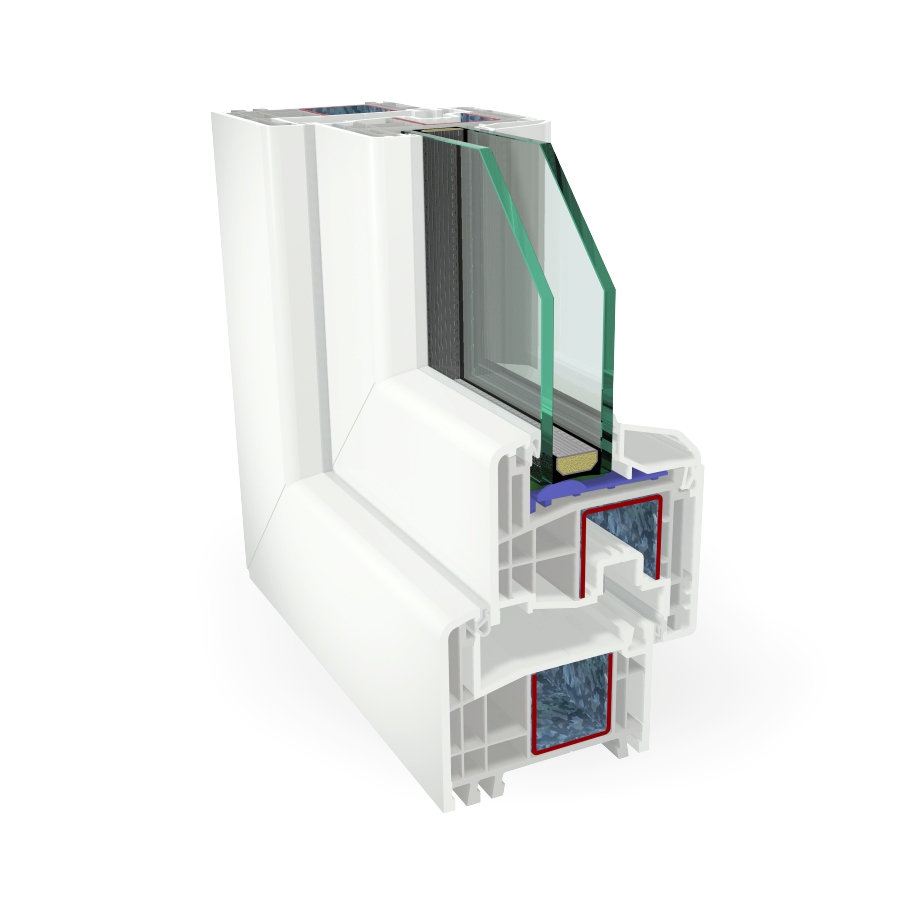

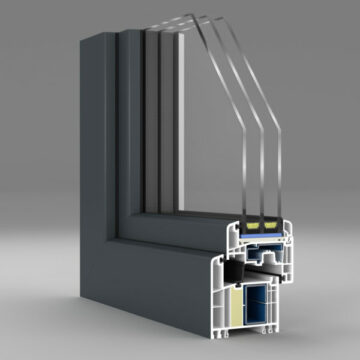

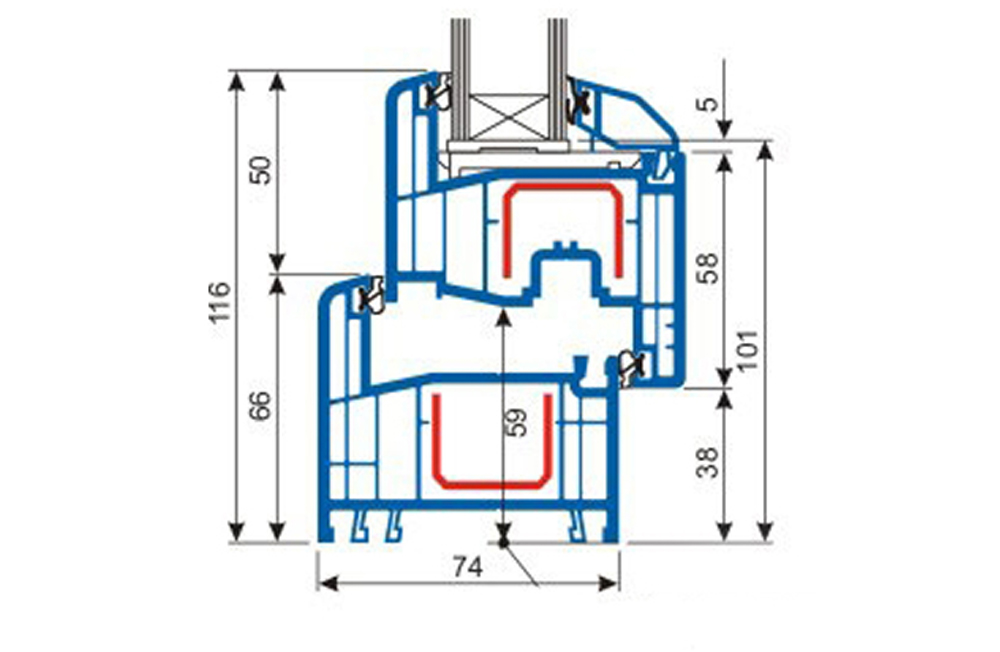

- 5 chambers

- Installation thickness of the profile 74 mm

- High static characteristics

- Modern acrylcolor and wood effect

The S 8000 IQ system has exceptional thermal insulation qualities and helps to save energy, which in turn leads to lower heating costs. The achieved heat transfer coefficient Uf=1.2W/m2K

The technique of increasing thermal insulation through multi-chamber profile constructions proves to be superior, as each of the six chambers participates in reducing unwanted heat losses.

In addition, the increased mounting thickness of the profile to 74 mm allows the use of large-sized fittings, thus ensuring the flawless use of the window for a very long time.

DESIGN

The S 8000 IQ system is characterized by an elegant appearance and perfectly combines aesthetics and functionality. A wide range of design solutions can be achieved and even the strict rules regarding buildings declared as national monuments can be met.

GEALAN is a traditional German company whose history began in 1921, when the Schlegelbei Hof was established.

In 1956, the company’s experience in new technologies and raw materials made it possible to create a new production-extrusion of PVC profiles for doors and windows. From that moment to the present day, it has been the cornerstone in the development of GEALAN Fenster-Systeme. As a result of continuous improvement efforts, GEALAN has the necessary experience and know-how in the extrusion of PVC profiles for doors and windows. To expand the services it offers to its customers in 1999 an advertising and marketing company was added to the GEALAN group.

The successful changes demonstrate GEALAN’s strength in innovative technology and production. As a result, GEALAN is among the best producers of PVC profiles in Europe.

Nowadays, the GEALAN Group is a strong partner in the market of PVC windows and doors. GEALAN factories develop the production process depending on the requirements of the European norms: DIN EN ISO 9001, according to which quality control begins with the inspection of raw materials and ends with the quality of the final product.

In 1980, GEALAN started production of colored PVC profiles using the co-extrusion method. The essence of this method consists in adding a layer of Plexiglas with a thickness of 0.3-0.7 mm to the profile surface at the same time as the extrusion. The co-extrusion process takes place at a very high temperature, as a result of which the two materials, which have similar characteristics, are inseparably connected to each other. The resulting profile surface is silky smooth, resistant to UV rays and atmospheric influences, antistatic and resistant to mechanical impacts.

In May 1997, GEALAN was successfully certified according to ISO 14001 standards. These environmental protection standards were integrated into the QSU management system and additionally certified according to ISO 9001:2000.